Insulated flexible Aluminum air duct is composed by inner tube, insulation and jacket.

1. Inner tube: is made of one foil band or two, which is spirally wound around high elastic steel wire; The foil could be laminated Aluminum foil, aluminised PET film or PET film.

Thickness of laminated Aluminum foil: 0.023mm (single side), 0.035mm (dual sides).

Thickness of Aluminised PET film: 0.016mm.

Thickness of PET film: 0.012mm.

Diameter of Bead wire: 0.96mm, 0.12mm.

Pitch of the helix: 25mm, 36mm.

2. Insulation: usually with centrifugal glass wool

Thickness: 25mm, 50mm.

Density: 16kg/m³, 20kg/m³, 24kg/m³.

3. Jacket: longitudinal seam jacket and circular seam jacket

3.1. Longitudinal seam jacket: It is made of a single piece of fabric circled into a cylindrical shape with a longitudinal seam. This structure is easy to crack when the the air duct is compressed or bent.

3.2. Circular seam jacket is made of one foil band or two,which is spirally wound with glass fiber in the middle, and the foil could be laminated Aluminum foil, aluminised PET film or PET film. The structure overcomes the shortcoming of longitudinal seam jacket---cracking easily while the duct is compressed or bent. The glass fiber reinforced the jacket.

There are three ways of glass fiber reinforcing the jacket:

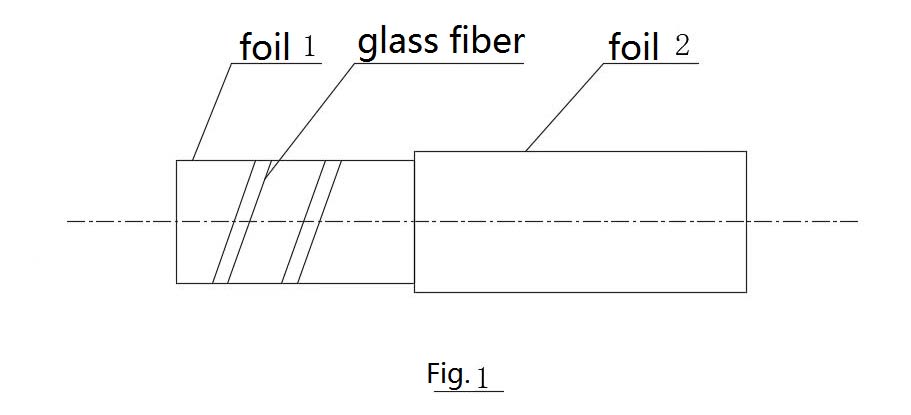

① Straight glass fiber reinforcement: With one or several straight glass fiber in between the two layers of films.(Figure 1).

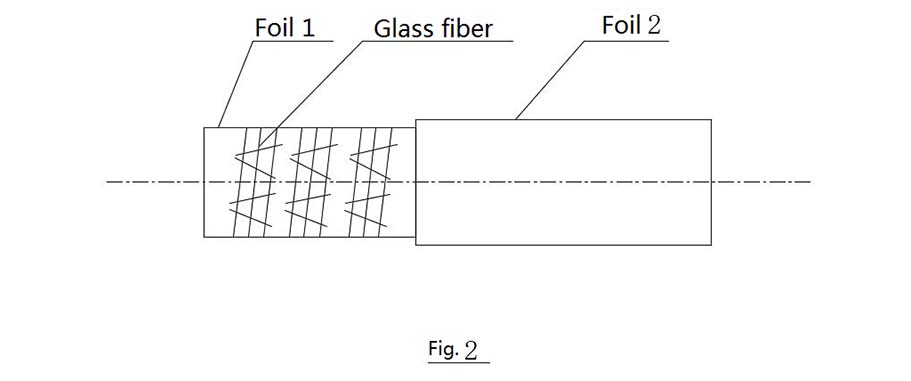

② π shape glass fiber reinforcement: Withπshape glass fiber mesh band in between the two layers of films. (Figure 2)

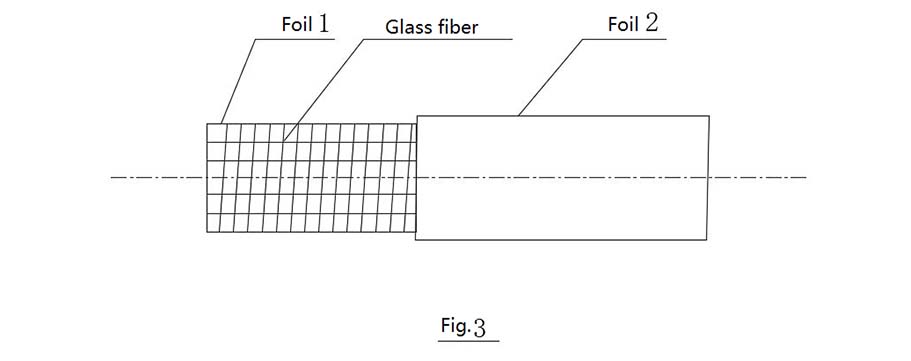

③ # shape glass fiber reinforcement: With one or several straight glass fiber spirally wound together in between the two layers of films; and with several glass fiber put in between the films in longitudinal direction; which form # shape in the jacket with the spirally wound glass fiber. (Figure 3)

The straight glass fiber reinforcement improves the warp strength of the jacket and can prevent the jacket from tearing in the longitudinal direction. And the πshape glass fiber reinforcement has better anti-tearing performance than the straight one. However, # shape glass fiber reinforcement combines the advantages of the former two. # shape is the best in all the three ways of reinforcements.

Post time: May-30-2022