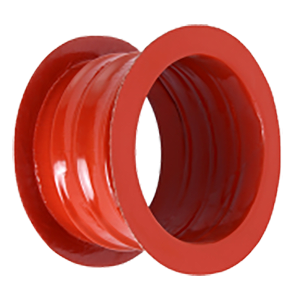

Non-metallic expansion joints

Non-metallic expansion joints are also called non-metallic compensators and fabric compensators, which are a type of compensators. Non-metallic expansion joint materials are mainly fiber fabrics, rubber, high temperature materials and so on. It can compensate the vibration of fans and air ducts and the deformation of pipes.

Application:

Non-metallic expansion joints can compensate for axial, lateral and angular directions, and have the characteristics of no thrust, simplified bearing design, corrosion resistance, high temperature resistance, noise reduction and vibration reduction, and are especially suitable for hot air ducts and smoke and dust ducts.

Connection method

- Flange connection

- Connection with pipe

Type

- Straight type

- Duplex type

- Angle type

- Square type

1 Compensation for thermal expansion: It can compensate in multiple directions, which is much better than the metal compensator that can only compensate in one way.

2. Compensation of installation error: Since the system error is unavoidable in the process of pipeline connection, the fiber compensator can better compensate the installation error.

3 Noise reduction and vibration reduction: The fiber fabric (silicone cloth, etc.) and the thermal insulation cotton body have the functions of sound absorption and vibration isolation transmission, which can effectively reduce the noise and vibration of boilers, fans and other systems.

4 No reverse thrust: Since the main material is fiber fabric, it is weakly transmitted. Using fiber compensators simplifies the design, avoids the use of large supports, and saves a lot of material and labor.

5. Good high temperature resistance and corrosion resistance: The selected fluoroplastics and silicone materials have good high temperature resistance and corrosion resistance.

6. Good sealing performance: There is a relatively complete production and assembly system, and the fiber compensator can ensure no leakage.

7. Light weight, simple structure, convenient installation and maintenance.

8. The price is lower than the metal compensator

Basic structure

1 skin

The skin is the main expansion and contraction body of the non-metal expansion joint. It is composed of multiple layers of silicone rubber or high-silica polytetrafluoroethylene with excellent performance and alkali-free glass wool. It is a high-strength sealing composite material. Its function is to absorb expansion and prevent leakage of air and rainwater.

2 stainless steel wire mesh

The stainless steel wire mesh is the lining of the non-metallic expansion joint, which prevents the sundries in the circulating medium from entering the expansion joint and prevents the thermal insulation material in the expansion joint from escaping outward.

3 Insulation cotton

Thermal insulation cotton takes into account the dual functions of thermal insulation and air tightness of non-metallic expansion joints. It is composed of glass fiber cloth, high silica cloth and various thermal insulation cotton felts. Its length and width are consistent with the outer skin. Good elongation and tensile strength.

4 Insulation filler layer

The thermal insulation filler layer is the main guarantee for the thermal insulation of non-metallic expansion joints. It is composed of high temperature resistant materials such as multi-layer ceramic fibers. Its thickness can be determined by heat transfer calculation according to the temperature of the circulating medium and the thermal conductivity of the high temperature resistant material.

5 racks

The frame is a contour bracket of non-metallic expansion joints to ensure sufficient strength and rigidity. The material of the frame should be adapted to the temperature of the medium. Usually at 400. Use Q235-A 600 below C. Above C is made of stainless steel or heat-resistant steel. The frame generally has a flange surface that matches the connected flue duct.

6 bezels

The baffle is to guide the flow and protect the thermal insulation layer. The material should be consistent with the medium temperature. Materials should be corrosion and wear resistant. The baffle should also not affect the displacement of the expansion joint.

Post time: Nov-10-2022