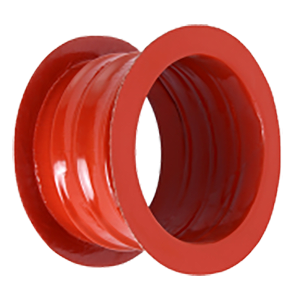

OEM/ODM China Stainless Steel Carbon Steel Wcb A216 Single Sphere Rubber Expansion Joint

Our staff are generally while in the spirit of “continuous improvement and excellence”, and while using the excellent high quality merchandise, favorable value and great after-sales services, we try to gain each customer’s have faith in for OEM/ODM China Stainless Steel Carbon Steel Wcb A216 Single Sphere Rubber Expansion Joint, Our service concept is honesty, aggressive, realistic and innovation. With your support, we will grow much better.

Our staff are generally while in the spirit of “continuous improvement and excellence”, and while using the excellent high quality merchandise, favorable value and great after-sales services, we try to gain each customer’s have faith in for China Rubber Expansion Joint and Flexible Expansion Joint, Insisting on the high quality generation line management and customers qualified assistance, we now have designed our resolution to provide our buyers using the to start with amount getting and just after services practical experience. Maintaining the prevailing friendly relations with our buyers, we however innovate our solution lists all of the time to satisfy the brand new demands and adhere to the most up-to-date development of the market in Malta. We’re ready to face the worries and make the improve to understand all the possibilities in international trade.

Application of Non-metal Fabric Expansion Joints

Corrugated Fabric Expansion Joints with revers are new kind of non-metal expansion joints. The typical advantages are lightweight, supple, hermetic, high working temperature, anti-corrosive,big compensation rate and easy installation. They are suitable for the flexible connection between different ventilation fans, ducts and pipework; can compensate the thermal deformation of pipework and release the pipework stress; reduce or weaken the vibration of the pipework; and make the installation of whole system easier.

Corrugated Fabric Expansion Joints are different from those traditional non-metal expansion joint. It is made of single layer or multiple layers of rubber and fabrics, laminated under high temperature and pressure; the revers is turned over and shaped once with special technics, which is different from the craftwork for producing traditional fabric expansion joints—- gluing, sewing, covering and flange pressing. And the special technics make our expansion joints overcome the traditional expansion joints’ weak points such as not-firmly laminated, not hermetic, leaking, heavy, hard for installation and maintenance.

Corrugated Fabric Expansion Joints connect to the flanges with its own rubber layer on the revers, the connection is very hermetic; and can sustain max 2MPa working pressure. The axial compression ratio, radial and rotational shifting are much better than traditional expansion joints. Our Corrugated Fabric Expansion Joints are very ideal for ventilation fans, pipework to reduce the system vibration, noise and stress. They are the best parts you should have for your system.

We use different kinds of fabrics to make the expansion joints according to our customers’ technical requirements and application environments, such as silicon rubber, fluorine rubber, Ethylene-Propylene-Diene Monomer(EPDM).

Recommended Application

● Process industry

● Petrochemical industry

● Chemical industry

● Pharmaceutical industry

● Toxic, hazardous, chemical media

● Residue and waste incineration

● Calcination

● Reduction

● Oil and gas industry

● Refining technology

● Power plant technology

● Pulp and paper industry

● Metal production and processing

● Cement industry

● Flue gas ducts

● Boiler inlets and outlets

● Pipe penetration

● Process lines

● Stacks

● Industries with higher requirements

Advantages

● Reduced pollution emissions

● Safe operation

● Significant reduction in primary energy consumption

● Long service life, low wear

● Predictable downtime

● Available as retrofit on existing systems

● Good flexibility

● High chemical resistance

● Reduced heat loss

● Minimal reaction force

※ Customized to fit actual working conditions and materials on request.

| Fabric Material | Weather proof functions | Physical functions | Chemical functions | working temperature | Not for | |||||||||||||||||

| ozene | oxide | sunlight | radiation | fabric thickness | pressure range | axial compression ratio (%) |

axial stretch ratio (%) |

radial shifting (%) |

suitable for fluids |

Hot H₂SO₄ | Hot H₂SO₄ | Hot HCL | Hot HCL | Anhydrous ammonia |

NaOH | NaOH | working temperature range |

Max continious working temperature |

temporary max working temperature |

|||

| fabric+gas seal layer | Positive pressure | Negative pressure | <50% | >50% | <20% | >20% | <20% | >20% | ||||||||||||||

| EPDM rubber(EPDM) | good | good | good | good | 0.75~3.0mm | max34.5 min14.5 |

max34.5 min14.5 |

60% | 10-20% | 5-15% | corrosive gas organic solvents general gas |

suitable (good) |

average or poor |

average | poor | suitable (good) |

suitable (good) |

suitable (good) |

-50~148℃ | 148℃ | 176℃ | Aliphatic hydrocarbons Aromatic hydrocarbons |

| Silicone Rubber(SL) | good | good | good | average | 0.6~3.0mm | max34.5 min14.5 |

max34.5 min14.5 |

65% | 10%~25% | 5%~18% | general gas | poor | poor | poor | poor | poor | suitable (good) |

average | -100~240℃ | 240℃ | 282℃ | Solvent oil acid alkali |

| Chlorosulfonated polyethylene rubber (CSM/Hypalon) |

good | good | good | good | 0.65~3.0mm | max34.5 min14.5 |

max34.5 min14.5 |

60% | 10-20% | 5-15% | corrosive gas organic solvents general gas |

suitable (good) |

average | average | poor | average | suitable (good) |

suitable (good) |

-40~107℃ | 107℃ | 176℃ | Concentrated hydrogen chloride |

| Teflon plastic (PTFE) | good | good | good | good | 0.35~3.0mm | max34.5 min14.5 |

max34.5 min14.5 |

40% | 5%~8% | 5%~10 | Most of the corrosive gas organic solvents |

suitable (good) |

suitable (good) |

suitable (good) |

suitable (good) |

suitable (good) |

suitable (good) |

suitable (good) |

-250~260℃ | 260℃ | 371℃ | Poor wear resistance |

| Fluororubber(FKM)/Viton | good | good | good | average | 0.7~3.0mm | max34.5 min14.5 |

max34.5 min14.5 |

50% | 10-20% | 5-15% | corrosive gas organic solvents general gas |

suitable (good) |

suitable (good) |

suitable (good) |

suitable (good) general |

poor | suitable (good) |

average | -250~240℃ | 240℃ | 287℃ | ammonia |

Our staff are generally while in the spirit of “continuous improvement and excellence”, and while using the excellent high quality merchandise, favorable value and great after-sales services, we try to gain each customer’s have faith in for OEM/ODM China Stainless Steel Carbon Steel Wcb A216 Single Sphere Rubber Expansion Joint, Our service concept is honesty, aggressive, realistic and innovation. With your support, we will grow much better.

OEM/ODM China China Rubber Expansion Joint and Flexible Expansion Joint, Insisting on the high quality generation line management and customers qualified assistance, we now have designed our resolution to provide our buyers using the to start with amount getting and just after services practical experience. Maintaining the prevailing friendly relations with our buyers, we however innovate our solution lists all of the time to satisfy the brand new demands and adhere to the most up-to-date development of the market in Malta. We’re ready to face the worries and make the improve to understand all the possibilities in international trade.